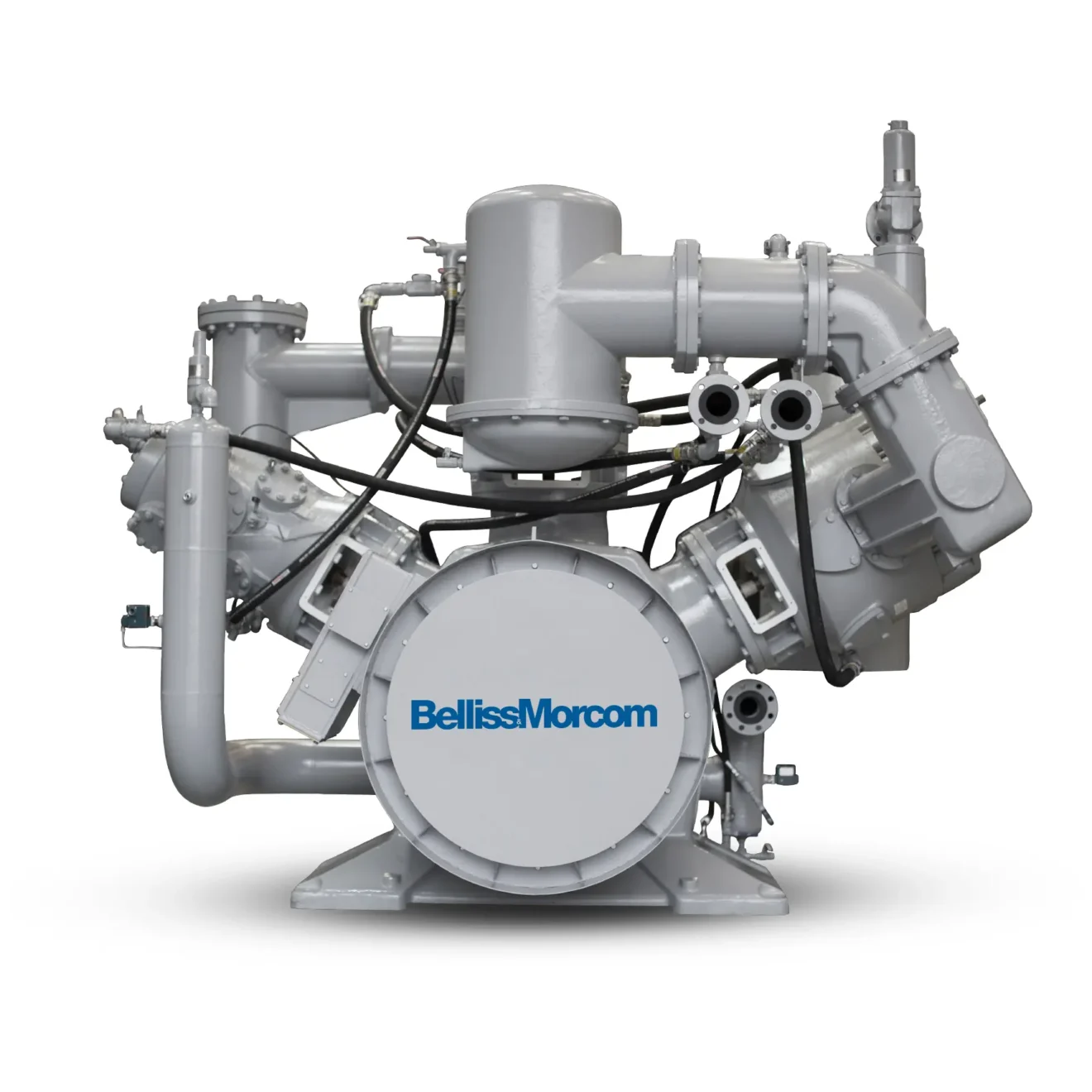

Efficient Reciprocating Air Compressor

For more than 170 years, Belliss & Morcom has been recognized worldwide for its high-pressure reciprocating air compressors. As a trusted supplier, we are dedicated to providing you with access to these industry-leading solutions.

Reach Out To Us

Built at the core of hardworking industries, our reciprocating air compressors supply clean, oil-free air and gas that drive critical heavy-duty operations. Knowing what matters most, we design our high-pressure compressors to guarantee maximum performance, reliability, and continuous operation.

Explore Our Range of Reciprocating Air Compressors

In the world of industry, every bit of performance counts, and being efficient is key. Our reciprocating air compressors, powered by shaftless motors, offer the lowest operational costs out there, ensuring that your investment in a Belliss & Morcom high-pressure air compressor boosts your profits.

Even tiny losses in how power moves from the compressor motor can lead to big wastes of energy and can hit your wallet hard. Inefficiencies in belt drive systems alone could hike up your energy costs by as much as 12%. That's why our high-pressure air compressors include a shaftless motor right from the start.With this compact design, all the motor's power goes straight to the air compressor's running gear without any loss, and it stays that way for the entire life of the machine. This means you begin with savings and keep on saving as the years roll by.

No Shaft, No Problem

The Belliss & Morcom shaftless motor requires no drive system maintenance. No belt tensioning, no belt replacement, no motor alignment, no coupling checks or maintenance – this is a zero-maintenance drive system providing a constant and 100% efficient power transmission.

Maximum Productivity

In critical operations, every second of uptime is precious. Routine maintenance can cut into your profits. Our distinct slanting design ensures our products are easy to maintain, which means Belliss & Morcom compressors do away with the costly regular servicing that others require.

Built To Last

For top-notch reliability, each part must be perfectly suited to the compressor's role. Settling for less can cost more over time. Some reciprocating air compressors on the market use heavy welded frames to manage support and reduce intense vibrations. This might seem cheaper upfront, but it introduces parts that can fail unexpectedly, leading to costly repairs. Our Belliss & Morcom compressors, with their unique diagonal frame, don't need external supports for stability or to control vibrations, reducing wear and saving you from frequent servicing and the risk of sudden breakdowns.

Since 1852, Belliss & Morcom has been committed to excellence as an industrial high-pressure air compressor manufacturer. Our dedication to superior construction and reliability is reinforced by our Belliss Xtra warranty program, extending beyond 5 years.

Water-Cooled Motor Protection

In harsh environments, at high altitudes or temperatures, where it is dusty or ventilation is limited, air-cooled motors can de-rate or even fail. Belliss & Morcom’s bespoke water cooled motors eliminate this risk. With IP56 protection and a cooling system that doesn’t rely on or impact the surrounding environment, our water cooled motors can run reliably where an air cooled motor can’t.

Unique Diagonal Design

The unique Belliss & Morcom ‘W’ design means each compression stage runs on its own cylinder line. This gives you an extra layer of reliability and efficiency. So whatever your system size and output, capacity control can be achieved in the most cost effective way possible.

Our efficient 50% load system manages smaller flow variations and allows tighter pressure bandwidth without the need for a variable speed drive (VSD). However, where required, Belliss & Morcom high pressure air compressors also offer a market leading VSD system. Combined with our 50% load and available running speed range, it offers unmatched output control - down to 30% of the maximum output.

Reduced Wear

Belliss & Morcom high pressure reciprocating air compressors feature a 45 or 60 degree incline. This reduces static piston ring loading by up to 29.3% compared with horizontal cylinder lines. It means less wear and completely eliminates the need for interim turning of either compression or bearing rings.

Ease of Access

As a result, our engineers have been able to move the largest piston off the vertical cylinder line, significantly improving access and reducing service complexity and downtime.

Compact Footprint

In busy production sites, space is always at a premium, so a smaller machine footprint can be a big advantage. Because of their unique diagonal design, Belliss & Morcom high pressure air compressors are significantly more compact than competitors’ equipment. It means more air delivered for a given amount of factory floor – and valuable extra space for productive activity.

Custom Design

Where your available space is limited, and yet you still require high performance, Belliss & Morcom can create a bespoke solution specifically for you. Our expert team has extensive experience of fitting complete systems in even the tightest of spaces. Our diagonal set up, water cooled motor and modular package mean our systems can operate effectively and efficiently where competitors’ simply can’t fit.

Oil-Free Reciprocating Air Compressors

Belliss & Morcom’s oil-free reciprocating air compressors are designed to optimize profitability through energy efficiency, reliability, ease of maintenance, and a lower total cost of ownership. They consume up to 10% less energy than screw compressors, potentially saving up to £20,000 annually, and have a long lifespan of up to 25 years with extended service intervals of 8,000 hours, minimizing downtime and capital expenditures. Offering up to 33% savings on total ownership costs over 10 years, these compressors feature advanced technologies such as shaftless motors for efficient power transfer, diagonal cylinder designs for reduced wear, and water-cooled motors for reliable operation in harsh environments. Compact and customizable, they are engineered to deliver consistent performance, ease of maintenance, and maximum productivity for demanding industrial applications.